Manufacturer for Grounding Busbar Insulator - DMC/BMC Molded electrical insulator – D&F

Manufacturer for Grounding Busbar Insulator - DMC/BMC Molded electrical insulator – D&F Detail:

DMC/BMC Material (DOUGH/BULK MOULDING COMPOUNDS)

Composed by unsaturated polyester glass resin, fiber glass, fillings, pigment, and other chemical agents, etc. It has good insulating property, high mechanical property, thermal resistance, fire retardant, corrosion stability, and especially the molding property such as good fluidity, lower molding pressure and temperature, short molding time. DMC/BMC is the best molding material for complex, thin wall and big molding parts.

D&F has his own workshops to do MC for our molded parts. According customers’ technical requirements, this workshop is capable of taking the different production formulas to produce the SMC or DMC material with different performances, then do the molded parts with some special mechanical strength and electrical strength.

Applications

The main function of the insulator is to firmly support and fix the current carrier conductor and form a good electrical insulation between the conductor and the ground.

Production Equipment

The workshop has 80 heat molding equipment with different pressure. The maximum pressure is from 100 Ton to 4300 Ton. The maximum size of molding products can reach 2000mm*6000mm. Any parts with complicated structure can be processed in these molding equipment by developing the mould,which can meet most users’ application requirements.

Quality Control

D&F can develop the moulds to do all molded insulator with different dimension as per the drawings. All size precision is controlled as per your drawings and GB/T1804-M (ISO2768-M). The following are the test equipment which can be used to test the electrical and mechanical properties.

Advantages

All technical engineers and production personnel have over 10 years of experience of doing the molding parts.

D&F has his own workshops to do the DMC /BMC for our insulators or other molded parts. According customers’ technical requirements, this workshop is capable of taking the different production formulas to produce the SMC or DMC material with different performances, then do the molded parts with some special mechanical strength and electrical strength.

D&F have his own special Precision machining workshop and technical team to design and produce customized moulds as per the users’ drawings & special technical requirements, then the molding workshop use the molding equipment to produce the structural parts for electrical insulation or other applications.

It can shorten the order lead time and ensure the products quality.

Besides, D&F also has the special workshop to design and produce the inserts used in the insulators and other molded parts.

All these advantages can help to reduce the product cost and improve the market response speed.

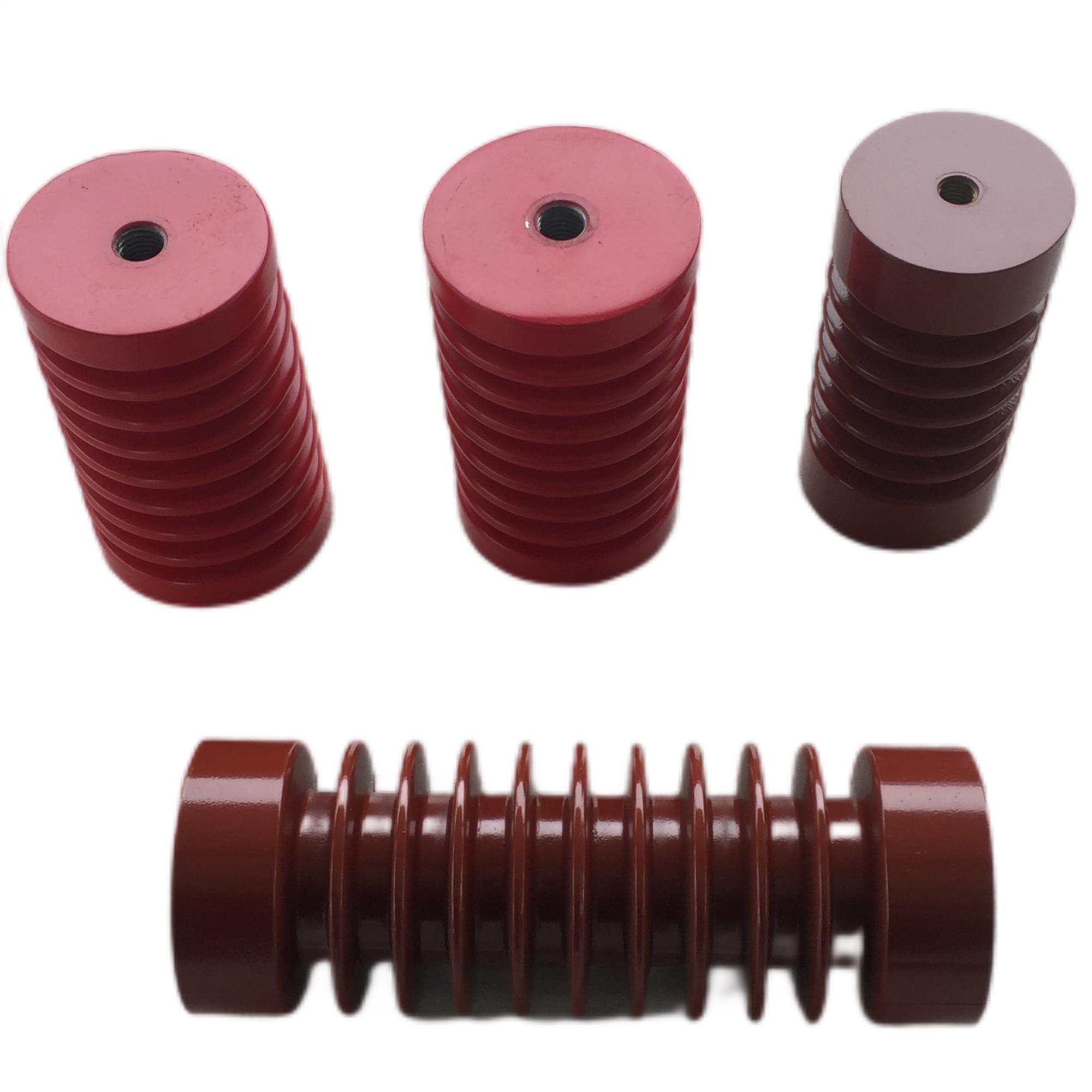

Product detail pictures:

Related Product Guide:

Good quality To start with,and Purchaser Supreme is our guideline to offer the top service to our customers.Presently, we've been seeking our best to be amongst the top exporters inside our industry to fulfill consumers extra need to have for Manufacturer for Grounding Busbar Insulator - DMC/BMC Molded electrical insulator – D&F , The product will supply to all over the world, such as: Spain, United Arab emirates, Turkey, We've been consistently broadening the market within Romania in addition to preparation punching in extra premium quality merchandise connected with printer on t shirt so that you can Romania. Most people firmly believe we've the whole capacity to provide you happy solutions.

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.