Manufacturer for Electrical Insulating Paper - D279 Epoxy Pre-impregnated DMD for dry type trasnformers – D&F

Manufacturer for Electrical Insulating Paper - D279 Epoxy Pre-impregnated DMD for dry type trasnformers – D&F Detail:

D279 is made from DMD and special epoxy heat resistant resin. It has the characteristics of long storage life, low curing temperature and short curing time. After being cured, it has excellent electrical properties, good adhesive and heat resistance.The heat resistance is Class F. It is also called as Prepreg DMD, pre-impregnaed DMD, flexible composite insulation paper for dry transformers.

Product Features

D279 epoxy pre-impregnated DMD has excellent electrical properties, good adhesive and heat resistance.

Applications

D279 epoxy pre-impregnated DMD is used for layer insulation or liner insulation of low-voltage copper/ aluminum foil winding in dry-type transformers as well as slot insulation and liner insulation in Class B and F electric motors and electric appliances. It is also called as Prepreg DMD, Prepreg insulation composite paper for dry type transformers.

Supply Specifications

Nominal width:1000 mm.

Nominal weight: 50±5kg /Roll.

The splices shall not be more than 3 in a roll.

Color: white or red color.

Appearance

Its surface should be flat, free of uneven resin and impurities affecting performances. While being de-coiled, its surface shall not be conglutinated each other. Free of such defects such as creases, bubbles and wrinkles.

Packing And Storage

D279 should be wrapped with plastic film then put in clean & dry carton

The storage life is 6 months at temperature of below 25℃ after leaving factory. If the storage duration is over 6 months, the product can still be used when being tested to be qualified. The product should be put and/or stored upright and keep away from fire, heat and direct sunshine.

Technical Performances

The standard performance values for D279 epoxy pre-impregnated DMD are shown in table 1 and the typical values are shown in table 2.

Table 1: Standard Performance value for D279 epoxy Prpreg DMD

| No. | Properties | Unit | Stand values | ||||

| 1 | Nominal thickness | mm | 0.16 | 0.18 | 0.20 | 0.23 | 0.25 |

| 2 | Thickness tolerance | mm | ±0.030 | ±0.035 | |||

| 3 | Grammage (for reference) | g/m2 | 185 | 195 | 210 | 240 | 270 |

| 4 | Tensile strength (MD) | N/10mm | ≥70 | ≥80 | ≥100 | ||

| 5 | Dissolvable resin content | g/m2 | 60±15 | ||||

| 6 | Volatile content | % | ≤1.5 | ||||

| 7 | Dielectric strength | MV/m | ≥40 | ||||

| 8 | Shear strength under tension | MPa | ≥3.0 | ||||

Table 2: Typical performance values for D279 epoxy Prepreg DMD

| No. | Properties | Unit | Typical values | ||||

| 1 | Nominal thickness | mm | 0.16 | 0.18 | 0.20 | 0.23 | 0.25 |

| Thickness tolerance | mm | 0.010 | 0.015 | ||||

| 2 | Grammage (for reference) | g/m2 | 186 | 198 | 213 | 245 | 275 |

| 3 | Tensile strength (MD) | N/10mm | 100 | 105 | 115 | 130 | 180 |

| 4 | Dissolvable resin content | g/m2 | 65 | ||||

| 5 | Volatile content | % | 1.0 | ||||

| 6 | Dielectric strength | MV/m | 55 | ||||

| 7 | Shear strength under tension | MPa | 8 | ||||

Application and Remarks

Recommended curing conditions

Table 2

| Temperature(℃) | 130 | 140 | 150 |

| Curing time(h) | 5 | 4 | 3 |

Production Equipment

We have two lines, the production capacity is 200T/month.

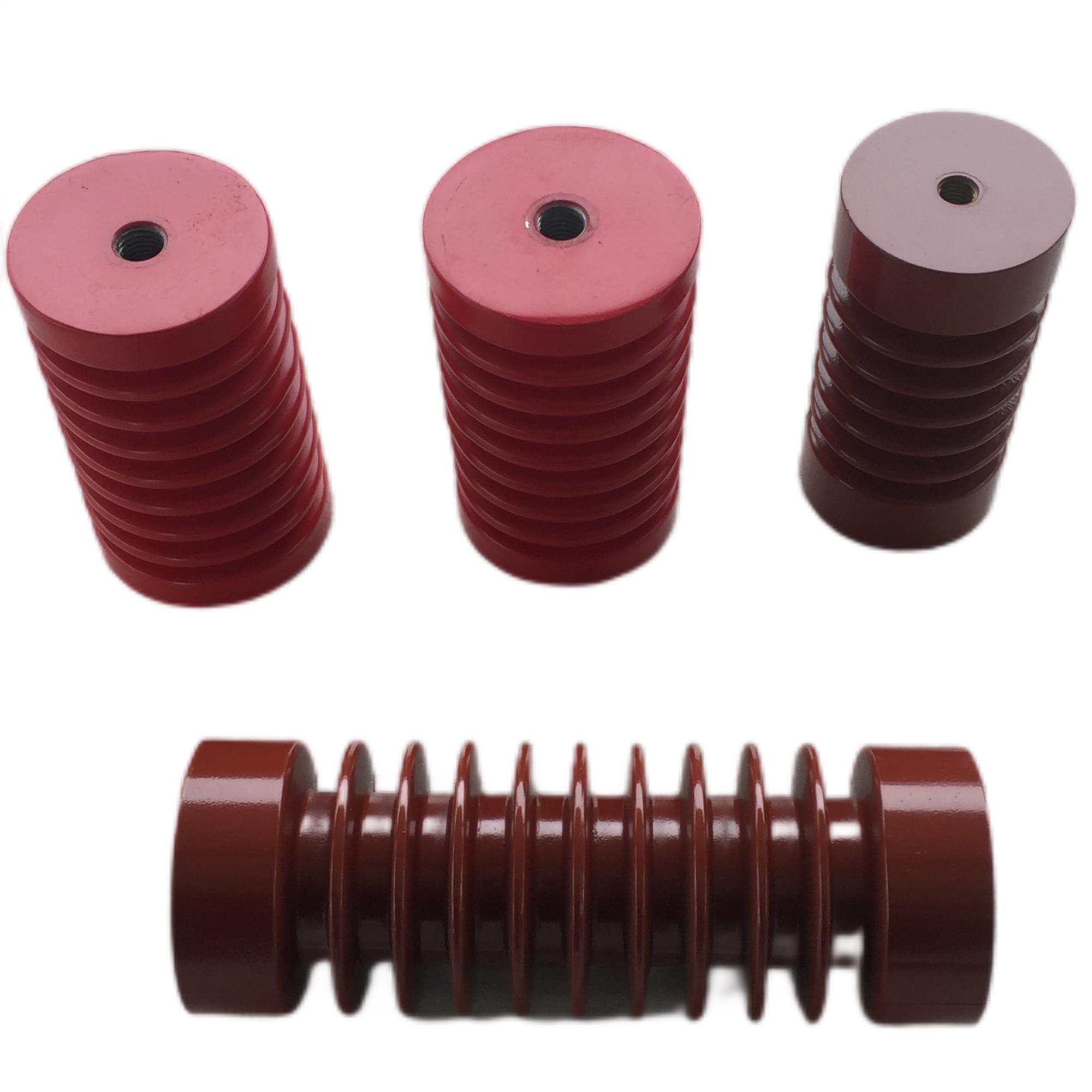

Product detail pictures:

Related Product Guide:

Our personnel are generally within the spirit of "continuous improvement and excellence", and using the excellent top quality goods, favorable rate and superior after-sales expert services, we try to win every customer's believe in for Manufacturer for Electrical Insulating Paper - D279 Epoxy Pre-impregnated DMD for dry type trasnformers – D&F , The product will supply to all over the world, such as: Colombia, Naples, USA, As the world economic integration bringing challenges and opportunities to the xxx industry, our company , by carrying on our teamwork, quality first, innovation and mutual benefit, are confident enough to supply our clients sincerely with qualified merchandise, competitive price and great service, and to build a brighter future under the spirit of higher, faster, stronger with our friends together by carrying on our discipline.

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!