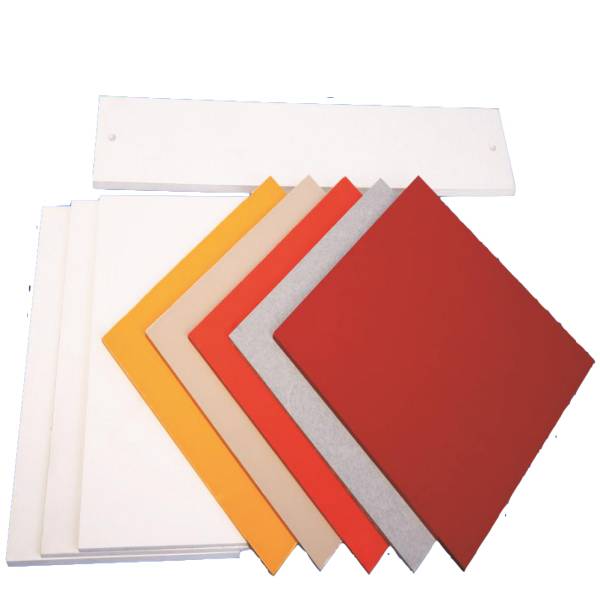

Manufacturer for Copper Laminated Flexible Shunts - DF205 Modified Melamine Glass Cloth Rigid Laminated Sheet – D&F

Manufacturer for Copper Laminated Flexible Shunts - DF205 Modified Melamine Glass Cloth Rigid Laminated Sheet – D&F Detail:

DF205 Modified Melamine Glass Cloth Rigid Laminated Sheet consists of woven glass cloth impregnated and bonded with a melamine thermosetting resin, laminated under high temperature and high pressure. The woven glass cloth shall be alkali-free.

With a high mechanical and dielectric properties and excellent arc resistance, the sheet is intended for electrical equipment as insulation structural parts, where high arc resistance is required. It also passed toxic and hazardous substance detection (RoHS Report). It is equivalent to NEMA G5 sheet, MFGC201, Hgw2272.

Available thickness: 0.5mm~100mm

Available sheet size:

1500mm*3000mm、1220mm*3000mm、1020mm*2040mm,1220mm*2440mm、1000mm*2000mm and other negotiated sizes.

The Nominal Thickness And Allowed Tolerance (mm)

| Nominal thickness | Deviation | Nominal thickness | Deviation | Nominal thickness | Deviation |

| 0.5 | +/-0.15 | 3 | +/-0.37 | 16 | +/-1.12 |

| 0.6 | +/-0.15 | 4 | +/-0.45 | 20 | +/-1.30 |

| 0.8 | +/-0.18 | 5 | +/-0.52 | 25 | +/-1.50 |

| 1 | +/-0.18 | 6 | +/-0.60 | 30 | +/-1.70 |

| 1.2 | +/-0.21 | 8 | +/-0.72 | 35 | +/-1.95 |

| 1.5 | +/-0.25 | 10 | +/-0.94 | 40 | +/-2.10 |

| 2 | +/-0.30 | 12 | +/-0.94 | 45 | +/-2.45 |

| 2.5 | +/-0.33 | 14 | +/-1.02 | 50 |

Bending Deflection for Sheets (mm)

|

Thickness |

Bending deflection |

|

|

1000(Ruler length) |

500(Ruler length) |

|

|

3.0~6.0 |

≤10 |

≤2.5 |

|

6.1~8.0 |

≤8 |

≤2.0 |

|

>8.0 |

≤6 |

≤1.5 |

Mechanical Processing

The sheets shall be free of cracks and scraps after being machined (punching & shearing).

Physical, Mechanical And Dielectric Properties

| No. | Properties | Unit | Standard value | Typical value | ||

| 1 | Density | g/cm3 | 1.90~2.0 | 1.95 | ||

| 2 | Water absorption(3mm) | mg | See the following table | 5.7 | ||

| 3 | Flexural strength, perpendicular to laminations (Lengthwise) | At normal condition | MPa | ≥270 | 471 | |

| 4 | Impact strength(Charpy, notch, lengthwise) | kJ/m2 | ≥37 | 66 | ||

| 5 | Tensile strength | MPa | ≥150 | 325 | ||

| 6 | Compressive strength | MPa | ≥200 | 309 | ||

| 7 | Adhesive/bond strength | N | ≥2000 | 4608 | ||

| 8 | Shear strength, parallel to laminations | MPa | ≥30 | 33.8 | ||

| 9 | Dielectric Strength,perpendicular to laminations ( in transformer oil at 90℃+/-2℃) | MV/m | ≥14.2 | 20.4 | ||

| 10 | Breakdown voltage,parallel to laminations (in transformer oil at 90℃+/-2℃) | kV | ≥30 | 45 | ||

| 11 | Insulation resistance, parallel to laminations | At normal condition | Ω | ≥1.0 x 1010 | 4.7 x 1014 | |

| After 24h in water | ≥1.0 x 106 | 2.9 x 1014 | ||||

| 12 | Dielectric dissipation factor 1MHz | – | ≤0.02 | 0.015 | ||

| 13 | Dielectric constant 1MHz | – | ≤5.5 | 4.64 | ||

| 14 | Arc resistance | s | ≥180 | 184 | ||

| 15 | Tracking resistance | PTI | V | ≥500 | PTI500 | |

| CTI | ≥500 | CTI600 | ||||

| 16 | Flammability | Grade | V-0 | V-0 | ||

Water Absorption

|

Average thickness of test samples (mm) |

Water absorption (mg) |

Average thickness of test samples (mm)

|

Water absorption (mg) |

Average thickness of test samples (mm)

|

Water absorption (mg) |

|

0.5 |

≤17 |

2.5 |

≤21 |

12 |

≤38 |

|

0.8 |

≤18 |

3.0 |

≤22 |

16 |

≤46 |

|

1.0 |

≤18 |

5.0 |

≤25 |

20 |

≤52 |

|

1.6 |

≤19 |

8.0 |

≤31 |

25 |

≤61 |

|

2.0 |

≤20 |

10 |

≤34 |

For sheet thicker than 25mm,it shall be machined to 22.5mm on one side. |

≤73 |

| Remarks:1 Remarks: If the caculated average of measured thickness is between two thcikness mentioned in this table, the values will be acuired by interpolation. If the caculated average of measured thickness is less 0.5mm, the vales will not be over 17mg. If the caculated average of measured thickness is over 25mm, the value will not be over 61mg.2 .If nominal thciness is more than 25mm,it shall be machined to 22.5mm on one side only. The machined side should be smooth. | |||||

Packing And Storage

The sheets shall be stored in a place where temperature is no higher than 40℃, and be placed horizontally on a bedplate with a height of 50mm or above. Keep away from fire, heat (heating apparatus) and direct sunshine. The storage life of sheets is 18 months from the date of leaving factory. If the storage duration is over 18 months, the product also could be used after being tested to be qualified.

Remarks and Precautions for Application

1 A high speed and small cutting depth shall be applied when machining because of sheets’ weak thermal conductivity.

2 Machining and cutting this product will release much dust and smoke. Suitable measures should be taken to ensure dust levels are within acceptable limits during operations. Local exhaust ventilation and using the suitable dust/particle masks are advised.

3 The sheets are subject to moisture after being machined, a coating of insulating vanish is recommended.

Production Equipment

The Package For Laminated Sheets

Product detail pictures:

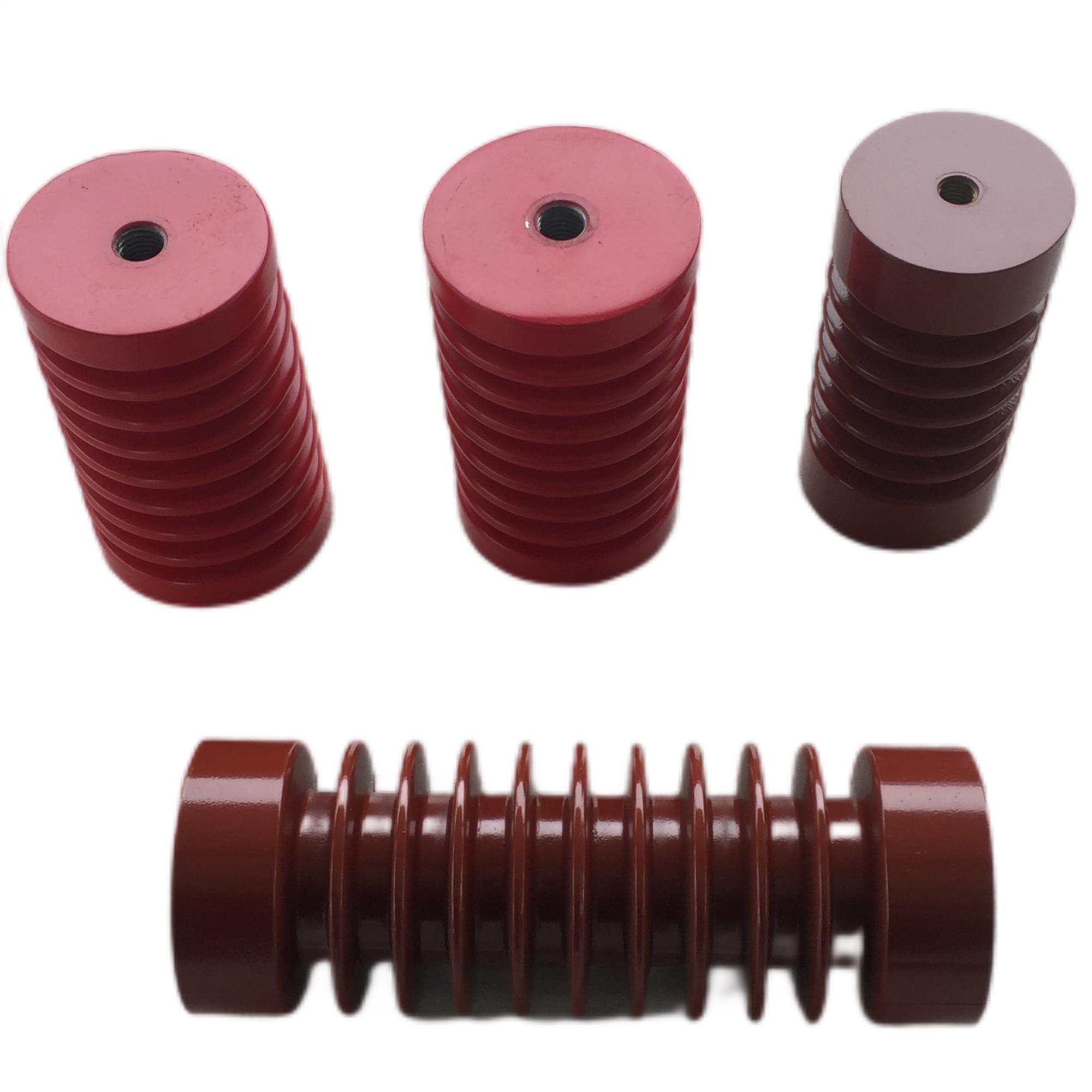

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" is definitely the persistent conception of our corporation to the long-term to establish alongside one another with customers for mutual reciprocity and mutual profit for Manufacturer for Copper Laminated Flexible Shunts - DF205 Modified Melamine Glass Cloth Rigid Laminated Sheet – D&F , The product will supply to all over the world, such as: Sierra Leone, Zambia, Mexico, Our production have been exported to more than 30 countries and regions as first hand source with lowest price. We sincerely welcome customers from both at home and abroad to come to negotiate business with us.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!