High definition Smc Sheet - D370 SMC Molded insulation sheet – D&F

High definition Smc Sheet - D370 SMC Molded insulation sheet – D&F Detail:

D370 SMC molded insulation sheet (D&F type number:DF370) is a kind of thermosetting rigid insulation sheet. It is made from SMC in mold under high temperature and high pressure. It is with UL certification and passed the test of REACH and RoHS, etc. It is also called as SMC sheet, SMC insulation board,etc.

SMC is a kind of sheet molding compound which consists of glass fiber reinforced with unsaturated polyester resin, filled with fire retardant and other filling substance.

SMC sheets have higher mechanical strength, dielectric strength, good flame resistance, tracking resistance, arc resistance and higher withstand voltage, as well as low water absorption, stable dimension tolerance and small bending deflection. SMC sheets are used for making all kinds of insulating boards in high or low voltage switch gears. It can also be used to process other insulation structural parts.

Thickness:2.0mm~60mm

Sheet size:580mm*850mm, 1000mm*2000mm,1300mm*2000mm, 1500mm*2000mm or other negotiated sizes

SMC

DMC

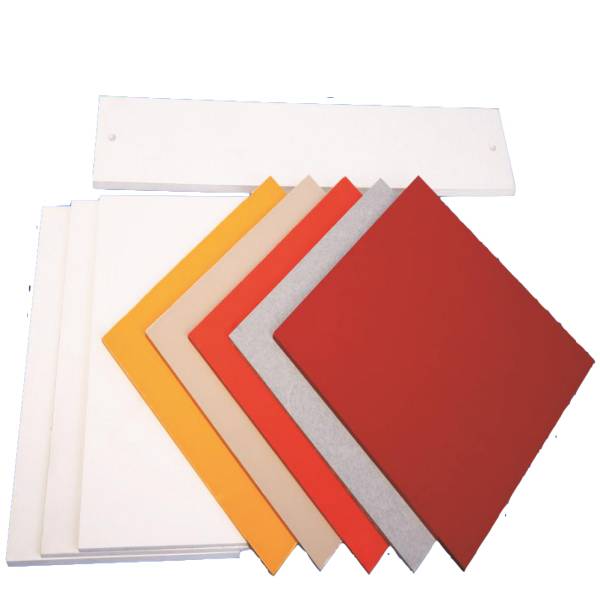

SMC sheets With different color

SMC sheets

Technical Requirements

Appearance

Its surface shall be flat and smooth, free from blisters, dents and obvious mechanical damages. The colour of its surface should be uniform, free from obvious exposed fiber. Free from obvious contamination, impurities and obvious holes. Free from delamination and crackles at its edges. If there are defects on the surface of the product, they can be patched. The superabundant ashes must be cleaned.

The bending deflection Unit: mm

| Spec | Dimension of shape | Nominal thickness S | Bending deflection | Nominal thickness S | Bending deflection | Nominal thickness S | Bending deflection |

| D370 SMC sheet | Length of all sides ≤500 | 3≤S<5 | ≤8 | 5≤S<10 | ≤5 | ≥10 | ≤4 |

| Length of any side | 3≤S<5 | ≤12 | 5≤S<10 | ≤8 | ≥10 | ≤6 | |

| 500 to 1000 | |||||||

| Length of any side ≥1000 | 3≤S<5 | ≤20 | 5≤S<10 | ≤15 | ≥10 | ≤10 |

Performance requirements

Physical, mechanical and electrical properties for SMC sheets

|

Properties |

Unit |

Standard value |

Typical value |

Test method |

||

| Density |

g/cm3 |

1.65—1.95 |

1.79 |

GB/T1033.1-2008 |

||

| Barcol hardness |

- |

≥ 55 |

60 |

ASTM D2583-07 |

||

| Water absorption, 3mm thickness |

% |

≤0.2 |

0.13 |

GB/T1034-2008 |

||

| Flexural strength,perpendicular to laminations | Lengthwise |

MPa |

≥170

|

243 |

GB/T1449-2005 |

|

| Crosswise |

≥150 |

240 |

||||

| Impact Strength, parallel to laminations(Charpy, unnotched) |

KJ/m2 |

≥60 |

165 |

GB/T1447-2005 |

||

| Tensile strength |

MPa |

≥55 |

143 |

GB/T1447-2005 |

||

| Tensile elasticity modulus |

MPa |

≥9000 |

1.48 x 104 |

|||

| Moulding shrinkage |

% |

- |

0.07 |

ISO2577:2007 |

||

| Compressive strength(perpendicular to laminations) |

MPa |

≥ 150 |

195 |

GB/T1448-2005 |

||

| Compressive modulus |

MPa |

- |

8300 |

|||

| Heat deflection temperature under load(Tff 1.8) |

℃ |

≥190 |

>240 |

GB/T1634.2-2004 |

||

| Coefficient of liner thermal expansion(20℃–40℃) |

10-6/K |

≤18 |

16 |

ISO11359-2-1999 |

||

| Electrical strength (in 25# transformer oil at 23℃+/-2℃,short-time test, Φ25mm/Φ75mm, cylindrical electrode ) |

KV/mm |

≥12 |

15.3 |

GB/T1408.1-2006 |

||

| Breakdown voltage ( parallel to laminations, in 25# transformer oil at 23℃+/-2℃, 20s step-by -step test, Φ130mm/Φ130mm, plate electrode ) |

KV |

≥25 |

>100 |

GB/T1408.1-2006 |

||

| Volume resistivity |

Ω.m |

≥1.0 x 1012 |

3.9 x 1012 |

GB/T1408.1-2006 |

||

| Surface resistivity |

Ω |

≥1.0 x 1012 |

2.6 x 1012 |

|||

| Relative permittivity (1MHz) |

- |

≤ 4.8 |

4.54 |

GB/T1409-2006 |

||

| Dielectric dissipation factor (1MHz) |

- |

≤ 0.06 |

9.05 x 10-3 |

|||

| Arc Resistance |

s |

≥180 |

181 |

GB/T1411-2002 |

||

|

Tracking resistance |

CTI

|

V |

≥600 |

600 Overpass |

GB/T1411-2002

|

|

|

PTI |

≥600 |

600 |

||||

|

Insulation resistance |

At normal condition |

Ω |

≥1.0 x 1013 |

3.0 x 1014 |

GB/T10064-2006 |

|

|

After 24h in water |

≥1.0 x 1012 |

2.5 x 1013 |

||||

|

Flammability |

Grade |

V-0 |

V-0 |

UL94-2010 |

||

|

Oxygen index |

℃ |

≥ 22 |

32.1 |

GB/T2406.1 |

||

|

Glow-wire test |

℃ |

>850 |

960 |

IEC61800-5-1 |

||

Withstand voltage

|

Nominal thickness(mm) |

3 |

4 |

5~6 |

>6 |

|

Withstand voltage in air for 1min KV |

≥25 |

≥33 |

≥42 |

>48 |

Inspection, Mark, Packaging and Storage

1. Each batch should be tested before dispatch.

2. According to the requirements of the customers, the test method of withstand voltage is negotiable according to the sheets or shapes.

3. It is packed by cardboard box on pallet. Its weight is not more than 500kg per pallet.

4. The shee ts shall be stored in a place where temperature is not higher than 40℃, and be placed horizontally on a bedplate with a height of 50mm or above. Keep away from fire, heat (heating apparatus) and direct sunshine. The storage life of sheets is 18 months from the date of leaving factory. If the storage duration is over 18 months, the product also could be used after being tested to be qualified.

5. Others shall accord with the stipulations of GB/T1305-1985,General rules for the inspection,marks,packing, transportation and storage of insulation thermosetting material.

Certification

Product detail pictures:

Related Product Guide:

That has a sound business enterprise credit rating, exceptional after-sales provider and modern producing facilities, we now have earned an superb standing amongst our buyers across the world for High definition Smc Sheet - D370 SMC Molded insulation sheet – D&F , The product will supply to all over the world, such as: Naples, Paris, Sao Paulo, We strongly believe that technology and service is our base today and quality will create our reliable walls of future. Only we have better and better quality , could we achieve our customers and ourselves, too. Welcome customers all over the word to contact us for getting further business and reliable relationships. We are always here working for your demands whenever you need.

Problems can be quickly and effectively resolved, it is worth to be trust and working together.