Factory making Epoxy Parts For Electric Power Transmission - Custom rigid copper or aluminum bus bar – D&F

Factory making Epoxy Parts For Electric Power Transmission - Custom rigid copper or aluminum bus bar – D&F Detail:

D&F has over 17 years of CNC machining experience. D&F can produce and supply all kinds of high-quality copper bus bars as per users’ drawings or technical requirements.

Rigid copper bus bar, It is CNC machined from copper sheets or copper bars. For the the long rectangles conductors with has cross section of rectangular or chamfering (rounded), generally the user will use the rounded copper bars to avoid point discharge. It plays the role of conveying current and connecting electrical equipment in the circuit.

Our rigid copper bus bar bar is processed in our automatic bus bar production line. According to customer’s technical drawings, we can produce a variety of high conductivity connection copper bar with various specifications & complex shape.

Our rigid copper bars are processed from T2Y2 copper material (C11000), the copper content is over more than 99.9%. All raw materials and finished parts have a 100% full inspection before production, quality can be assured.

According user’s requirement, the copper bar can be tin plated, nickel plated or silver plated or coated with heat shrink insulating tubes with different voltage requirement.

Products Features

Rigid copper /aluminum bus bars have the advantages of low resistivity, high current-carrying capacity, high conductivity and larger bending degree.

Surface Treatment

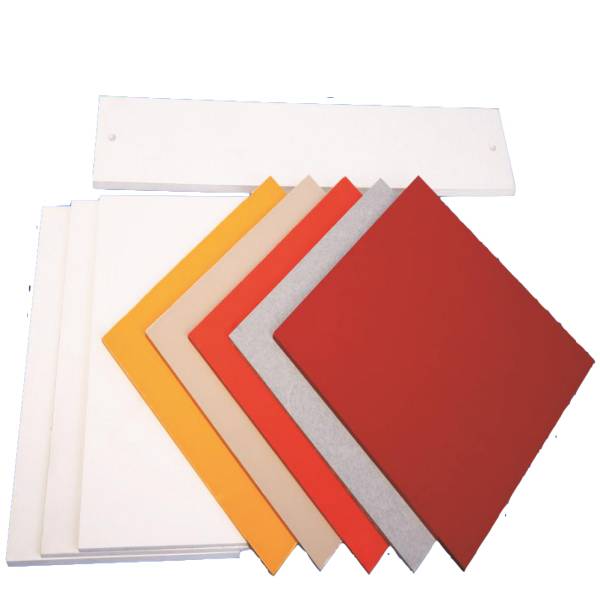

Tin, nickel, silver, gold plating. Coating epoxy insulation layer and heat shrink tubes.

Applications

Rigid copper bar is a kind of high current conductive product, which is suitable for high and low voltage electrical equipment, especially in complete sets of distribution devices, switch contacts, electric power distribution equipment, bus bar duct and other electrical engineering, but also widely used in metal smelting, electrochemical electroplating, chemical caustic soda and other super current electrolytic smelting engineering.

Production Equipment For Rigid Copper or Aluminum Bus Bar.

Product detail pictures:

Related Product Guide:

Our personnel are always inside the spirit of "continuous improvement and excellence", and together with the outstanding excellent goods, favorable price and good after-sales services, we try to gain every customer's trust for Factory making Epoxy Parts For Electric Power Transmission - Custom rigid copper or aluminum bus bar – D&F , The product will supply to all over the world, such as: Florence, Belize, Malawi, Make sure you genuinely feel free to send us your requirements and we are going to respond for you asap. We now have got a skilled engineering group to serve for your just about every detailed needs. Cost-free samples could be sent to suit your needs personally to understand much more information. In an effort to meet your requires, be sure to seriously feel free to make contact with us. You may send us emails and contact us directly. Moreover, we welcome visits to our factory from around the globe for much better recognizing of our organization. nd objects. In our trade with merchants of numerous countries, we usually adhere for the principle of equality and mutual benefit. It is really our hope to market, by joint efforts, each trade and friendship to our mutual advantage. We look forward to getting your inquiries.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!