Custom CNC Machining Insulation Structural Parts

Custom CNC machining Parts

All these insulation structural parts can be processed from such electrical insulation sheets as G10/G11/FR4/FR5/EPGC308, UPGM203 (GPO-3), EPGM sheet and all kinds of insulation profiles produced by pultrusion or molding technology.

The production scales and production capacity are in the forefront of the same industry. The manufacturing technology is leading in China. Based on the users’ drawings and other special technical requirements, we can do all kinds of structural parts or components by CNC machining technology. These structural parts are widely used for electrical insulation or other different applications in electrical equipment.

All size precision is controlled as per your drawings and GB/T1804-M (ISO2768-M).

We thank for your trusting us and sharing the drawings, we'll produce the high-quality machining parts to ensure the best solutions to the electrical structural insulation.

CNC Machining Parts for UHVDC Transmission

Processed from Epoxy Glass cloth laminated sheets

CNC Machining Parts for UHVDC Transmission

Processed from Epoxy Glass cloth laminated sheets

CNC Machining Parts for UHVDC Transmission

Processed from Epoxy Glass cloth laminated sheets

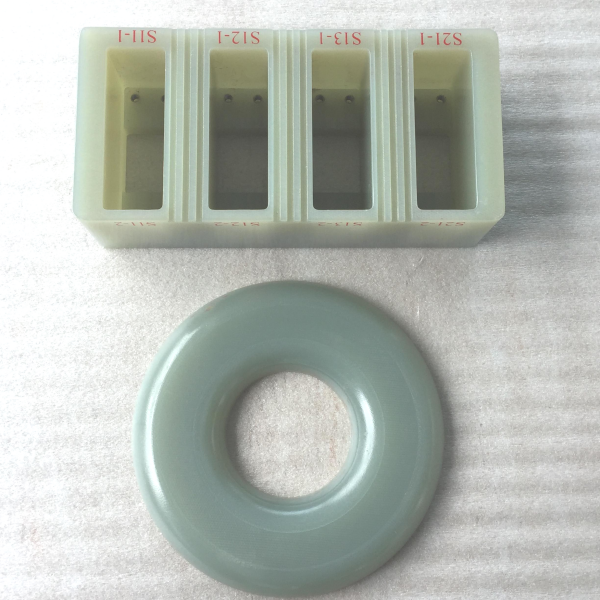

CNC Machining insulation structural parts / components for the special electrical equipment

Processed from Epoxy glass cloth laminated sheets,SMC sheet,GPO-3 sheets or molding insulation profiles

CNC Machining insulation structural parts / components for the special electrical equipment

Processed from Epoxy glass cloth laminated sheets,SMC sheet,GPO-3 sheets or molding insulation profiles

Applications

These products are widely used as the core insulating structural parts or components in the following fields:

1) New energy, such as wind power, Photovoltaic generation and nuclear power,etc.

2) High-voltage electrical equipment,such as high-voltage frequency converter, high-voltage soft start cabinet, high-voltage SVG and Reactive power compensation,etc.

3) Large and medium generators,such as hydraulic generator and turbo-dynamo.

4) Special electric motors, such as traction motors,metallurgical crane motors,rolling motors and the other motors in aviation, water transportation and mineral industry,etc.

5) Dry type transformers

6) UHVDC transmission.

7) Rail transit.

Production Equipment

Myway Technlogy CNC machining workshop owns over 120 machining equipments with different machining size and dimension accuracy. The maximum machining size of insulation part is 4000mm*8000mm.

The machining dimension is strictly as per the requirement of ISO2768-M (GB/T 1804-M), the best dimension accuracy can reach ±0.01mm.

We can do all custom machining parts as per your drawings and technical requirement.

Quality Control

All size precision is strictly controlled as per user’s drawings and ISO2768-m standards.

Especially we are also the manufacturer for insulation sheets (EPGC sheet, EPO-3, EPGM sheet) and insulation profiles which are the raw material for machining parts. Moreover we have our advanced R&D labs to develop the insulation materials, as well as the testing labs to test material’s mechanical strength & electrical strength, so we can well control the products quality from the source. All these gives our products a better price advantage.

Besides, During the whole production,including sawing, we have professional quality personnel to inspect the part’s dimension & tolerance based on drawings and ISO2768-m, the products are 100% inspected to ensure all parts can meet users’ technical requirement.