Best quality Insulating Paper - 6641 F-class DMD flexible composite insulation paper – D&F

Best quality Insulating Paper - 6641 F-class DMD flexible composite insulation paper – D&F Detail:

6641 Polyester film/polyester non-woven flexible laminate (Class F DMD) insulation paper is a three-layer flexible laminate made of high melting-point polyester film and excellent hot-rolling polyester non-woven fabric. Each side of the polyester film (M) is bounded by one layer of polyester non-woven fabric (D) with Class F adhesive.

Product Features

6641 F-class DMD flexible composite insulation paper has excellent thermal resistance, electrical, mechanical and impregnated properties.

Applications & Remarks

6641 F-class DMD insulation paper has such advantages: lower price, excellent flexibility, high mechanical & electrical properties, convenient application. It has also good compatibility with many kinds of impregnating varnish.

It is suitable for slot insulation, inter phase insulation and liner insulation in F-class electric motors.

According to customer’ request, we can also produce such two-layer or five-layer flexible composite as F-class DM, F-class DMDMD,etc.

Supply Specifications

Nominal width:1000 mm.

Nominal weight: 50+/-5kg /Roll. 100+/-10kg/roll, 200+/-10kg/roll

The splices shall not be more than 3 in a roll.

Color: white, blue, pink or with D&F printed logo.

Technical Performances

The standard values for 6641 are shown in Table 1 and relevant typical values shown in Table 2.

Table 1: Standard performance values for 6641 F-class DMD insulation paper

| No. | Properties | Unit | Standard performance values | |||||||||

| 1 | Nominal thickness | mm | 0.15 | 0.18 | 0.2 | 0.23 | 0.25 | 0.3 | 0.35 | 0.4 | ||

| 2 | Thickness tolerance | mm | ±0.020 | ±0.025 | ±0.030 | ±0.030 | ±0.030 | ±0.035 | ±0.040 | ±0.045 | ||

| 3 | Grammage (for reference) | g/m2 | 155 | 195 | 230 | 250 | 270 | 350 | 410 | 480 | ||

| 4 | Tensile strength | MD | Not folded | N/10mm | ≥80 | ≥100 | ≥120 | ≥130 | ≥150 | ≥170 | ≥200 | ≥300 |

| After folded | ≥80 | ≥90 | ≥105 | ≥115 | ≥130 | ≥150 | ≥180 | ≥220 | ||||

| TD | Not folded | ≥80 | ≥90 | ≥105 | ≥115 | ≥130 | ≥150 | ≥180 | ≥200 | |||

| After folded | ≥70 | ≥80 | ≥95 | ≥100 | ≥120 | ≥130 | ≥160 | ≥200 | ||||

| 5 | Elongation | MD | % | ≥10 | ≥5 | |||||||

| TD | ≥15 | ≥5 | ||||||||||

| 6 | Breakdown voltage | Room temp. | kV | ≥7.0 | ≥8.0 | ≥9.0 | ≥10.0 | ≥11.0 | ≥13.0 | ≥15.0 | ≥18.0 | |

| 155℃+/-2℃ | ≥6.0 | ≥7.0 | ≥8.0 | ≥9.0 | ≥10.0 | ≥12.0 | ≥14.0 | ≥17.0 | ||||

| 7 | Bonding property at room temp | - | No delamination | |||||||||

| 8 | Bonding property at 180℃+/-2℃, 10min | - | No delamination,no bubble,no adhesive flow | |||||||||

| 9 | Bonding property when affected by damp | - | No delamination | |||||||||

| 10 | Temperature index | - | ≥155 | |||||||||

Table 2: Typical performance values for 6641 F-class DMD insulation paper

| No. | Properties | Unit | Typical performance values | |||||||||

| 1 | Nominal thickness | mm | 0.15 | 0.18 | 0.2 | 0.23 | 0.25 | 0.3 | 0.35 | 0.4 | ||

| 2 | Thickness tolerance | mm | 0.005 | 0.005 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | ||

| 3 | Grammage | g/m2 | 138 | 182 | 207 | 208 | 274 | 326 | 426 | 449 | ||

| 4 | Tensile strength | MD | Not folded | N/10mm | 103 | 137 | 151 | 156 | 207 | 244 | 324 | 353 |

| After folded | 100 | 133 | 151 | 160 | 209 | 243 | 313 | 349 | ||||

| TD | Not folded | 82 | 127 | 127 | 129 | 181 | 223 | 336 | 364 | |||

| After folded | 80 | 117 | 132 | 128 | 179 | 227 | 329 | 365 | ||||

| 5 | Elongation | MD | % | 14 | 12 | |||||||

| TD | 18 | 12 | ||||||||||

| 6 | Breakdown voltage | Room temp. | kV | 8 | 10 | 12 | 12 | 14 | 15 | 16 | 28 | |

| 155±2℃ | 7 | 9 | 11 | 11 | 13 | 14 | 14.5 | 25 | ||||

| 7 | Bonding property at room temp | - | No delamination | |||||||||

| 8 | Bonding property at 180℃+/-2℃, 10min | - | No delamination, no bubble, no adhesive flow | |||||||||

| 9 | Bonding property when affected by damp | - | No delamination | |||||||||

Test Method

As per the stipulations in Part Ⅱ: Test Method, Electrical Insulating Flexible Laminates, GB/T 5591.2-2002 (MOD with IEC60626-2: 1995).

Packing And Storage

6641 is supplied in rolls, sheet or tape and packed in cartons or/and pallets.

6641 should be stored in clean & dry warehouse with temperature below 40℃. Keep away from fire, heat and direct sunshine.

Production Equipment

We have tow lines, the production capacity is 200T/month.

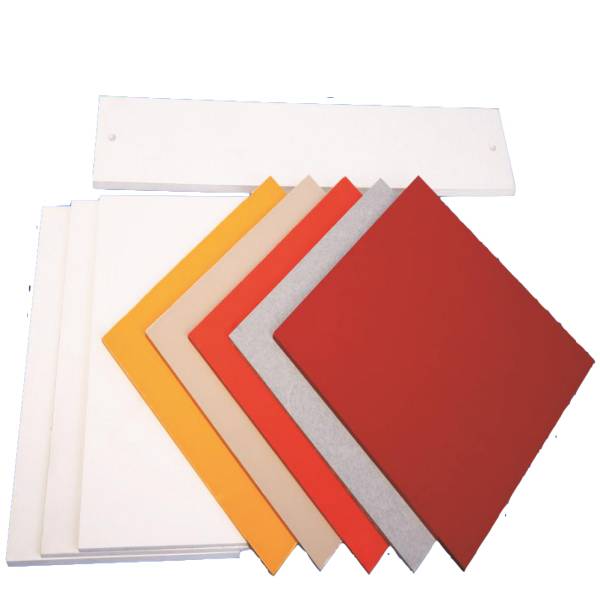

Product detail pictures:

Related Product Guide:

We have been also concentrating on enhancing the things management and QC method so that we could preserve terrific edge inside the fiercely-competitive enterprise for Best quality Insulating Paper - 6641 F-class DMD flexible composite insulation paper – D&F , The product will supply to all over the world, such as: Sierra Leone, Jordan, Senegal, Make sure you genuinely feel free to send us your requirements and we are going to respond for you asap. We now have got a skilled engineering group to serve for your just about every detailed needs. Cost-free samples could be sent to suit your needs personally to understand much more information. In an effort to meet your requires, be sure to seriously feel free to make contact with us. You may send us emails and contact us directly. Moreover, we welcome visits to our factory from around the globe for much better recognizing of our organization. nd objects. In our trade with merchants of numerous countries, we usually adhere for the principle of equality and mutual benefit. It is really our hope to market, by joint efforts, each trade and friendship to our mutual advantage. We look forward to getting your inquiries.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!