2022 High quality 6641 F-Dmd Electrical Insulating Paper Composite Material - 6643 F-class DMD (DMD100)flexible composite insulation paper – D&F

2022 High quality 6641 F-Dmd Electrical Insulating Paper Composite Material - 6643 F-class DMD (DMD100)flexible composite insulation paper – D&F Detail:

6643 Modified Polyester film/polyester non-woven flexible laminate is a kind o fthree–layer 100% epoxy resin saturated flexible composite insulation paper in which each side of the polyester film (M) is bonded with one layer of polyester non-woven fabric (D), then coated with F-class electrical insulating resin. 6643 flexible electrical insulation paper is used as the slot insulation, interphase insulation and liner insulation in F class electric motors, especially suitable for mechanized inserting slot process. 6643 passed SGS test for toxic and hazardous substance detection. It is also called as F class DMD, DMD100, DMD-100 electrical insulation composite material for electric motors.

Product Features

With coated heat-resistant resin which encapsulates the inner polyester film & adhesive, thus 6643 has excellent heat resistance property, excellent mechanical properties, excellent electrical properties and higher thermal resistance.

Applications

With coated heat-resistant resin, its surface is more smooth. It is suitable for mechanized inserting slot process.

6643 is used for slot insulation, inter phase insulation and liner insulation in F class electric motors, especially suitable for mechanized inserting slot process.

Supply Specifications

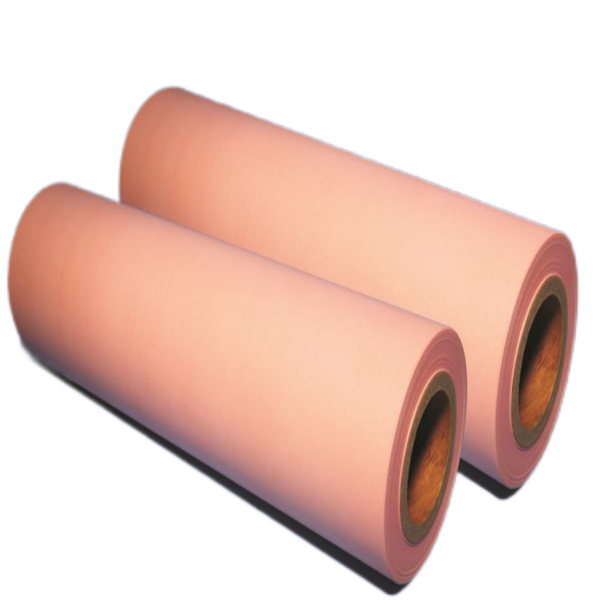

Nominal width:1000 mm.

Nominal weight: 50+/-5kg /Roll. 100+/-10kg/roll, 200+/-10kg/roll

The splices shall not be more than 3 in a roll.

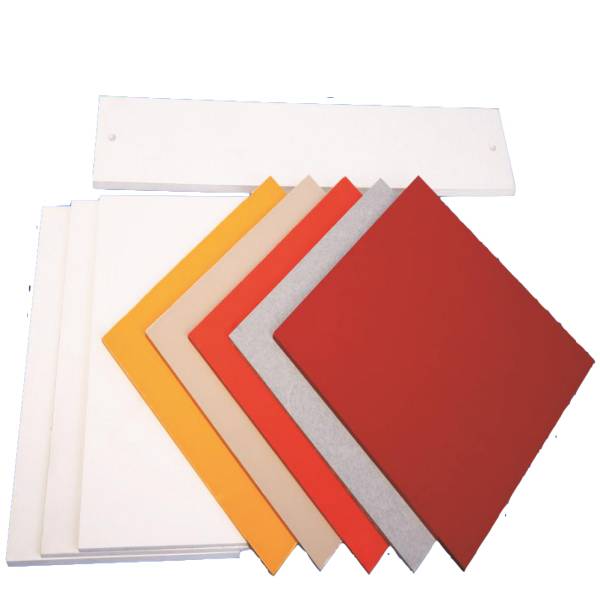

Color: white, blue, pink or with D&F printed logo.

Performance Requirements

The standard values for 6643 are shown in Table 1 and relevant typical values shown in Table 2.

Table1: Standard performance values for 6643 DMD 100 flexible insulation paper

| No. | Properties | Unit | Standard performance values | ||||||||||||||

| 1 | Structure | mil | 2/2/2 | 2/3/2 | 2/4/2 | 3/3/3 | 2/5/2 | 2/6/2 | 3/5/3 | 2-7.5-2 | 3-7.5-3 | 2002/10/2 | 2003/10/3 | 2-14-2 | 3-14-3 | ||

| 2 | Nominal thickness | mm | 0.15 | 0.18 | 0.2 | 0.23 | 0.23 | 0.25 | 0.28 | 0.3 | 0.35 | 0.36 | 0.4 | 0.45 | 0.5 | ||

| 3 | Thickness tolerance | mm | ±0.020 | ±0.025 | ±0.030 | ±0.030 | ±0.030 | ±0.030 | ±0.030 | ±0.035 | ±0.040 | ±0.040 | ±0.040 | ±0.045 | ±0.050 | ||

| 4 | PET film’s thickness | mm | 0.05 | 0.075 | 0.1 | 0.075 | 0.125 | 0.15 | 0.125 | 0.188 | 0.188 | 0.25 | 0.25 | 0.35 | 0.35 | ||

| 5 | Grammage | g/m2 | 160 | 210 | 245 | 255 | 265 | 310 | 325 | 360 | 400 | 445 | 505 | 580 | 640 | ||

| 6 | Tensilestrength | MD | Not folded | N/10mm | ≥90 | ≥110 | ≥130 | ≥120 | ≥150 | ≥170 | ≥170 | ≥200 | ≥220 | ≥260 | ≥300 | ≥330 | ≥360 |

| After folded | ≥80 | ≥100 | ≥110 | ≥105 | ≥120 | ≥140 | ≥150 | ≥180 | ≥200 | ≥220 | ≥240 | ≥280 | ≥300 | ||||

| TD | Not folded | ≥80 | ≥100 | ≥110 | ≥105 | ≥120 | ≥140 | ≥150 | ≥180 | ≥200 | ≥220 | ≥240 | ≥280 | ≥300 | |||

| After folded | ≥70 | ≥80 | ≥100 | ≥95 | ≥110 | ≥130 | ≥130 | ≥150 | ≥170 | ≥200 | ≥220 | ≥260 | ≥280 | ||||

| 7 | Breakdown Voltage | Room temp. | kV | ≥7.0 | ≥8.0 | ≥9.0 | ≥8.0 | ≥11.0 | ≥12.0 | ≥11.0 | ≥13.0 | ≥15.0 | ≥17.0 | ≥18.0 | ≥20.0 | ≥22.0 | |

| 8 | Heating influence180℃+/-2℃,10min | - | No delamination, no bubble, no adhesive flow. | ||||||||||||||

| Note*: Grammage values are only for reference. It can also depend on user’s special requirement if applicable. | |||||||||||||||||

Table 2 Typical performance values for 6643 DMD 100 flexible insulation paper

| No. | Properties | Unit | Typical performance values | ||||||||||||||

| 1 | Structure | mil | 2/2/2 | 2/3/2 | 2/4/2 | 3/3/3 | 2/5/2 | 2/6/2 | 3/5/3 | 2-7.5-2 | 3-7.5-3 | 2002/10/2 | 2003/10/3 | 2-14-2 | 3-14-3 | ||

| 2 | Nominal thickness | mm | 0.16 | 0.18 | 0.21 | 0.23 | 0.23 | 0.26 | 0.28 | 0.3 | 0.35 | 0.36 | 0.4 | 0.45 | 0.5 | ||

| 3 | Thickness tolerance | mm | 0.015 | 0.018 | 0.02 | -0.01 | 0.015 | 0.015 | 0.018 | 0.02 | 0.024 | 0.018 | 0.02 | 0.025 | 0.03 | ||

| 4 | PET film’s thickness | mm | 0.05 | 0.075 | 0.1 | 0.075 | 0.125 | 0.15 | 0.125 | 0.188 | 0.188 | 0.25 | 0.25 | 0.35 | 0.35 | ||

| 5 | Grammage | g/m2 | 165 | 210 | 245 | 255 | 270 | 327 | 330 | 365 | 400 | 445 | 519 | 580 | 640 | ||

| 6 | Tensilestrength | MD | Not folded | N/10mm | 130 | 170 | 210 | 180 | 230 | 158 | 270 | 290 | 223 | 345 | 305 | 420 | 425 |

| After folded | 130 | 160 | 200 | 180 | 220 | 132 | 270 | 270 | 201 | 335 | 242 | 420 | 425 | ||||

| TD | Not folded | 100 | 140 | 200 | 150 | 210 | 138 | 240 | 320 | 205 | 380 | 243 | 450 | 455 | |||

| After folded | 100 | 140 | 200 | 150 | 210 | 123 | 240 | 310 | 173 | 370 | 223 | 450 | 455 | ||||

| 7 | Breakdown Voltage | Room temp. | kV | 8 | 12 | 13 | 12 | 14 | 15 | 14 | 21 | 21 | 22 | 23 | 28 | 29 | |

| 8 | Heating influence180℃+/-2℃,10min | - | No delamination, no bubble, no adhesive flow | ||||||||||||||

Packing And Storage

6643 is supplied in rolls, sheet or tape and packed in cartons or/and pallets

6643 should be stored in clean & dry warehouse with temperature below 40℃. Keep away from fire, heat and direct sunshine.

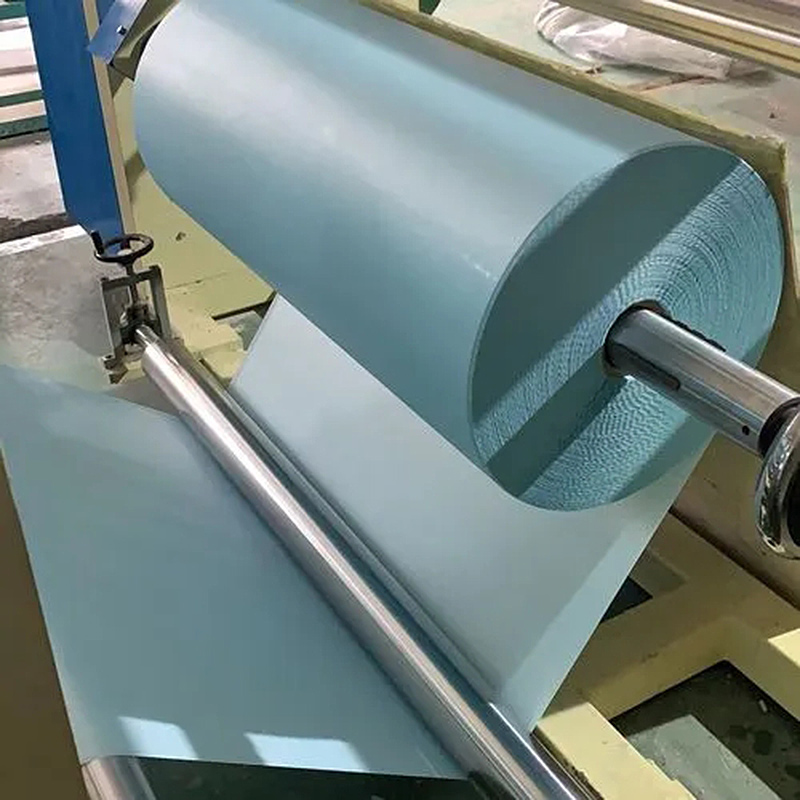

Production Equipment

We have tow lines, the production capacity for flexible capability is 200T/month.

Product detail pictures:

Related Product Guide:

Our goods are commonly recognized and reliable by consumers and may satisfy continually developing economic and social needs for 2022 High quality 6641 F-Dmd Electrical Insulating Paper Composite Material - 6643 F-class DMD (DMD100)flexible composite insulation paper – D&F , The product will supply to all over the world, such as: California, Japan, Argentina, We have 48 provincial agencies in the country. We also have stable cooperation with several international trading companies. They place order with us and export products to other countries. We expect to cooperate with you to develop a larger market.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!